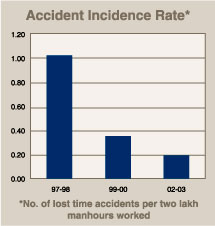

ITC benchmarks against international

best practices in the areas of Occupational Health and Safety. All Units of the Company

target to attain zero-accident levels through comprehensive risk assessment and

minimization and elimination of potential hazards. All ITC Units are mandated by policy to

record and recall incidents and address the Safety issues involved therein.

All ITC Units identify potential

Occupational Health and Safety hazards, whether physical or chemical. These are eliminated

or controlled to ensure that exposures are well within the specified and applicable

standards. ITC strives to provide safeguards of international standards for all plant and

machinery in each of its Units.

ITC accords high priority to fire safety.

All ITC locations deploy the latest comprehensive fire prevention and control technology.

|

|

| |

|

All

employees undergo rigorous training in fire prevention and evacuation techniques. The

number of fire accidents has reduced from 9 in 1997-98 to only one minor fire

accident in 2002-03 |

|

| |

|

|

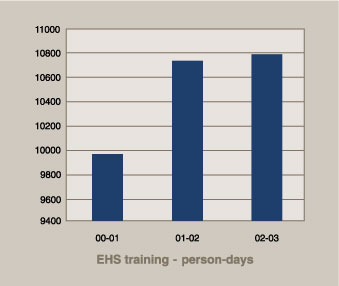

EHS training in ITC is focused on

building competency in employees to manage all the significant EHS aspects of operations.

The Company imparts general EHS training to all employees, with a three-year refresher

span. Specialized training in electrical and fire safety, risk assessment, waste |

|

management etc. is imparted to

employees dealing specifically with these issues. ITC invested 10,784 person-days in

EHS-related training in 2002-03. A quarter of the training related to Environment issues,

while the balance addressed Safety and Occupational Health. |

|

|