Sustainability

All ITC units are required to minimise water consumption and undertake measures to

ensure sustainability of water sources, e.g. wherever water is drawn from underground

sources like tubewells, strict surveillance on the water table is maintained. Measures

like rainwater harvesting are implemented to ensure sustainability of these water sources.

Benchmarking ‘specific water consumption’

Of the total 24.98 million KL of water drawn by ITC units, 91.28% (22.80 million KL)

was used by the three large paperboards and specialty paper units. Special efforts were,

therefore, directed towards water conservation and reducing specific water consumption in

these units.

Production Versus Fresh Water Intake for Bhadrachalam Paperboard

Unit (base year 1998-99 taken as 100)

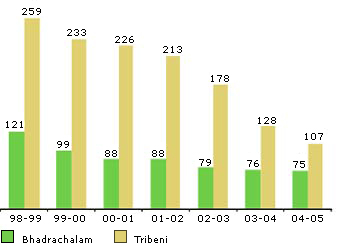

In the Bhadrachalam pulp and paperboards unit, while the production since 1998-99 has

gone up by 60%, actual water consumption has gone down by 1%. Further efforts and

improvements are in progress to substantially reduce fresh water requirement per tonne of

paperboards.

ITC’s specialty paper unit at Tribeni produces very fine papers (as low as 21

GSM). This unit achieved a 16.4% reduction in fresh water consumption per tonne of paper

in 2004-05 (i.e. 6.5% less fresh water intake than last year, in spite of an additional

production of 11.7%). This is specially significant since Tribeni had reported a 28%

reduction in specific water consumption in 2003-04.

|

|

Specific Water

Consumption for Bhadrachalam and Tribeni Units (KL/Tonne)

All the other units of ITC also continued their significant efforts to reduce specific

water consumption. ITC’s cigarette manufacturing units brought down specific water

consumption from 7.5 KL (2003-04) to 7.2 KL (2004-05) per million cigarettes. This

compares well with the specific water consumption of 8.01 KL per million cigarettes

reported by British American Tobacco in its Social Report 2004-05.

Zero Effluent Discharge

The degree of closure of the water cycle is the best indicator of efforts and initiatives

taken by a unit to minimise fresh water consumption.

ITC’s Cigarette factories at Bengaluru & Saharanpur, the ITC Group Research

& Development Centre at Bengaluru, the Leaf processing plant at Anaparti, Packaging

& Printing factory at Tiruvottiyur, the Cast coating plant at Bollarum, ITC Hotel

Sonar Bangla Sheraton & Towers at Kolkata and WelcomHotel Rajputana Palace Sheraton at

Jaipur did not discharge any waste water/effluent during the year. The treated effluent

was recycled/used for cooling towers, flushing toilets, gardening and other similar

activities within the premises.

Rainwater Harvesting

ITC’s endeavours towards sustainability go beyond the corporate boundary. Apart from

each unit of the Company implementing rainwater harvesting, the Company supports watershed

projects in water stressed areas, as described in the ‘Social Performance’

section of this report. The rainwater harvesting efforts in different units range from

rooftop rainwater harvesting in smaller units to total rainwater collection/charging

aquifers. |