Social Performance

Labour Practices and Decent Work

Occupational Health and Safety

Occupational Health and Safety

ITC gives special emphasis to the Occupational Health & Safety of its employees (including that of service providers) and all visitors to its establishments. This is ensured through strict adherence to Corporate Environment, Health & Safety Guidelines, which have incorporated best international standards and practices. Corporate resources and expert third party agencies audit all ITC establishments on a periodic basis in order to verify compliance. These reports are reviewed at the Board level.

Towards Zero Accident

All our factories, hotels and large offices have established Environment, Health & Safety (EHS) Management systems with designated roles and responsibilities, competent EHS resources and safety infrastructure, which are under constant upgradation to comply with best international standards. In addition, strong employee involvement is encouraged through participation in suggestion schemes, celebration of EHS events etc.

A continual process of risk assessment has been institutionalised across Businesses wherein risks are systematically identified and mitigation plans implemented. All new projects and major renovation jobs are reviewed and vetted at the design stage by EHS experts and engineering control measures are implemented together with the project. Pre commissioning audits are also conducted to ensure compliance to all EHS requirements.

A comprehensive incident/accident reporting system has been established in all Units. These incidents/accidents undergo a thorough investigation for identifying root causes and accordingly, corrective/preventive measures are initiated. The findings and recommendations are also discussed in the Safety Committee meetings to ensure complete management and employee buy in.

In order to disseminate the learnings from accidents, details of serious accidents, along with the root cause analysis and proposed corrective measures are communicated across the Company. This enables Units to be equipped for spearheading proactive measures that can eliminate/control similar situations.

|

|

Lost Time Accidents, Injury Rate and Lost Day Rate

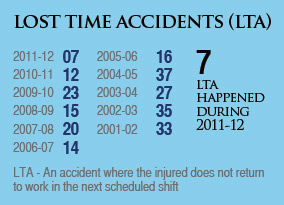

In ITC, Lost Time Accident (LTA) is defined as an accident where the injured is not able to come back to work for the next scheduled shift. This definition is more stringent than the ‘Reportable Accident’ as per the Factories Act, 1948, which is defined as an accident where an injured person is unable to resume duty within 48 hours after the accident.

There was however 1 very unfortunate fatal accident reported from the Specialty Papers Unit of Tribeni in 2011-12, wherein a skilled employee was seriously injured during maintenance work on a compressor, and passed away after a month of treatment. Based on detailed investigation of the accident, necessary corrective action has been implemented in all Units, which have similar equipments.

Lost day rate, defined as the number of days lost due to accidents for every 2,00,000 person hours, for the year 2011-12 was 25.3 (2.23 in 2010-11). This was mainly due to the fatal accident in Tribeni, which resulted in 48,000 man-hours lost on account of fatality (as per the Indian Standard IS: 3786-1983).

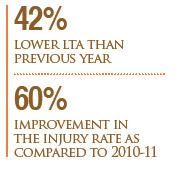

Injury rate, the frequency of injuries in relation to total time worked, has been brought down considerably. There has been an improvement of 60% in the injury rate as compared to 2010-11, despite significant growth in all Businesses. This reflects a consistent decline in the injury rate as has been illustrated below.

|

|

|