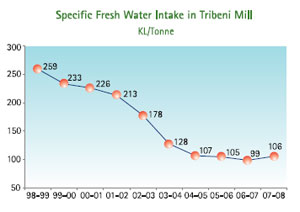

Tribeni unit Tribeni unit

The Tribeni mill, where larger quantities of water are

required for manufacture of specialty paper, has implemented

significant water reduction initiatives to achieve a 59%

reduction in specific fresh water intake since 1998-99.

Kovai unit

Our water conservation measures in the Kovai unit have

yielded positive results. The mill consumed only 17.31 KL of

fresh water per tonne of paperboards production in 2007-08

compared to 21.01 KL per tonne in 2006-07, a 17.6%

reduction.

Other Businesses undertook

proactive initiatives to minimise specific fresh water

consumption through water audits and implementation of

recommendations, deployment of best practices and

technologies along with greater employee participation.

The Cigarettes business continued to improve specific water

utilisation. The business used 4.9 KL of water per million

cigarettes (equivalent), an improvement of 8.2% compared to

5.4 KL per million cigarette (equivalent) in the previous

year. This compares favourably with the specific water

consumption of 4.85 KL per million cigarette (equivalent)

reported by British American Tobacco - British American

Tobacco - Sustainability Report 2007.

In 2007-08, Munger, Bengaluru and Saharanpur Cigarette

factories reduced specific water consumption by 14.1%, 8.4%

and 7.4%, respectively over the previous year.

Other units with exemplary performance in reducing specific

water consumption this year are the Packaging & Printing

unit at Tiruvottiyur (35.5%), Leaf Processing unit at

Anaparti (19.7%), ITC Hotels Maratha (17.1%) and Maurya

(11.1%).

|