Closing the water loop in a factory/hotel not only minimises fresh water usage, but also prevents pollution of the environment including that of fresh water sources. Significant endeavour has been made to recycle the entire treated wastewater through use in flushing toilets, cooling towers, gardening, etc.

Our Cigarette factories at Bengaluru, Saharanpur, Leaf plants at Anaparti and Chirala, Packaging & Printing unit at Tiruvottiyur, Research Centres at Bengaluru and Rajahmundry, Paperboards unit at Bollaram, ITC Green Centre at Gurgaon, Hotels ITC Sonar and Sheraton Rajputana reused/recycled their entire treated effluent.

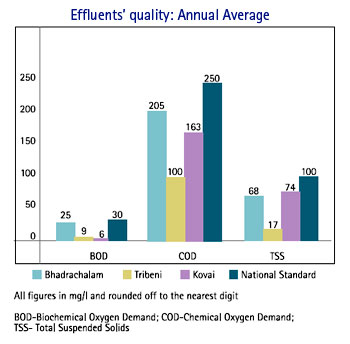

Three Paper & Paperboards mills, alone, generate 97.8 % of the total effluents in ITC. All the effluent parameters in these mills (as shown in the graph) & other ITC units are significantly better than the prescribed standards. |

OZONE BLEACHING

Bhadrachalam unit, this year, has introduced a cutting edge, high consistency Ozone delignification process named Ze Trac.

Ze Trac Ozone being a stronger oxidant than Chlorine requires smaller reaction systems and apart from being eco-friendly (it does not produce undesirable by-products, such as AOX), results in improved brightness, pulp strength and cost efficiency.

Bhadrachalam pioneered Elemental Chlorine Free (ECF) technology in India, in 2002. Successful implementation of Ozone Bleaching, the first in India and second in Asia, demonstrates ITC’s commitment to enlarging its positive environmental footprint and achieving higher levels of Triple Bottom Line performance. The adoption of such contemporary, eco-friendly technologies have yielded encouraging results which include:

- Lower operating costs

- Nearly 50% reduction in Specific Chlorine dioxide consumption

- Enhanced pulp quality

- Very significant reduction in Adsorbable Organic Halides in the effluents

|

|